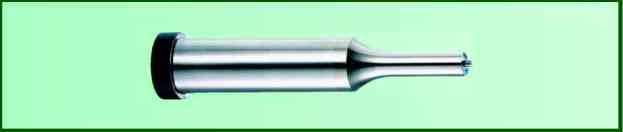

with stepped point and spring loaded ejector pin to DIN ISO 8020, type F

|

Item no.: |

217. . . base length l2 = 10 mm |

Hardness: | Shaft: | Material HSS HRC 64 ± 2 |

| 218. . . base length l2 = 13 mm | Material CPM 10 V HRC 62 ± 2 | |||

| 219. . . base length l2 = 17 mm | ||||

| The 4th digit of the item no. | Head: | Material HSS | ||

|

|

indicates the material, see How to order | and CPM 10 V HRC 50 ± 5 | ||

| Version: | Hardened, tempered, shaft fine ground | |||

| finished. | How to order: | For punch type F | ||

| Completely assembled with coil spring, | Cutting diameter d1 = 5 mm | |||

| grub screw and ejector. Spring pressure | Shaft diameter d3 = 13 mm | |||

| of ejector can be adjusted at grub screw | Total length l1 = 80 mm | |||

| on head. | High speed steel (HSS): | |||

|

|

||||

| Material: | HSS = High speed steel | Punch ISO 8020 | ||

| CPM 10V= High performance powdered steel | F-HSS 5 x 13 x 80 | |||

| For other materials see from (Material Table) | Item no.: 2193.05.13.080 | |||

| d1 | Gradation | d2 | d3 | r | l2 | l1 | |||

| j 6 | d1 | 0 | m5 | + 0,1 | + 0,5 | + 0,5 | |||

| - 0,15 | 0 | 0 | + 0,2 | ||||||

| 71 | 80 | 90 | 100 | ||||||

| 1,6 bis 5,9 | 0,1 | 9 | 6 | 0,3 | 10 | ■ | ■ | ■ | ■ |

| 2,5 bis 7,9 | 11 | 8 | 13 | ■ | ■ | ■ | ■ | ||

| 4,0 bis 9,9 | 13 | 10 | 17 | ■ | ■ | ■ | ■ | ||

| 5,0 bis 12,9 | 16 | 13 | 0,4 | ■ | ■ | ■ | ■ | ||

| 8,0 bis 15,9 | 19 | 16 | ■ | ■ | ■ | ■ | |||

| 12,0 bis 19,5 | 0,5 | 24 | 20 | ■ | ■ | ■ | |||

| 16,5 bis 24,5 | 29 | 25 | ■ | ■ | ■ | ||||