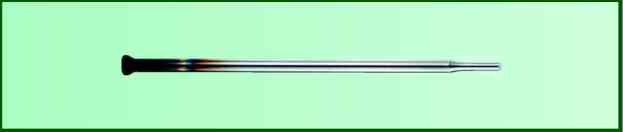

and stepped shaft to 5.5 mm cutting diameter to DIN 9861 standard part 2, type CA, type C

|

Item no.: |

114... | Hardness: | Sahft: | Material WS |

| The 4th digit of the item no. | and HWS HRC 62 ± 2 | |||

| indicates the material, see | Material HSS HRC 64 ± 2 | |||

| How to order | ||||

|

Version: |

Hardened, tempered with fine ground | Head: | Material WS HRC 45 ± 5 | |

| finished shaft. head hot forged and annealed. | Material HWS | |||

| With permissible thickening under head | and HSS HRC 50 ± 5 | |||

| (d4) to DIN 9861 standard part 2. | ||||

| Punches made from HWS are temper resistant | How to order: | For punch type CA | ||

| to 520 °C. | Cutting diameter d1 = 1,7 mm | |||

| Shaft diameter d3 = 2,0 mm | ||||

|

Materials: |

WS = Tool steel of type | Total length l1 = 80 mm | ||

| 1.2067 or similar | High carbon high chrome steel (HWS): | |||

| HWS = High carbon high chrome steel | ||||

| HSS = High speed steel | Punch DIN 9861 | |||

| For other materials see | CA-HWS 1,7 × 2 × 80 | |||

| (Material Tabel) | Item no. 1142.17.2.080 | |||

|

d1 h6 |

Gradation |

l1 + 0,5 0 |

d2 |

d3 h6 |

d4 |

l2 + 0,5 0 |

l3 Max |

h + 0,2 0 |

r | |||

| above | To |

Tolerance |

||||||||||

| 0,5 | 1,4 | 0,1 | 71 | 80 | 2,2 | ± 0,05 | 1,5 |

d3 +0,03 |

7 | 5 | 1,11 |

0,4+0,3 0 |

| 0,5 | 1,9 | 3,0 | ± 0,1 | 2 | 1,37 | |||||||

| 1,6 | 2,9 | 4,5 | 3 | 1,80 |

0,6+0,4 0 |

|||||||

| 2,5 | 3,5 | 0,5 | 5,5 | 4 | 10 | |||||||

| 3,5 | 4,5 | 6,5 | ± 0,2 | 5 | 6 | |||||||

| 4,5 | 5,5 | 8,0 | 6 | 2,23 |

1,0+0,5 0 |

|||||||

Lengths: The following lengths 60, 70, and 90 mm are also available in limited numbers from stock.